It is taking a few trial test prints to check my CAD efforts are producing what I need.

The sign will be made with seven individual letters.

Just working on the first letter at the moment.

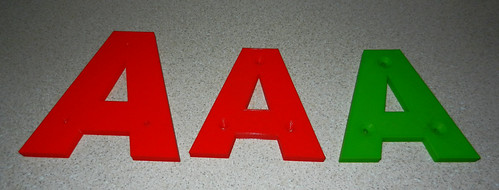

I started with a letter height of 120mm with three holes for screws.

That was bigger than needed really and took about 5 hours to print.

For a second test print I reduced the height to 100mm - much better.

Also at Adrian's suggestion I tried to make countersunk holes (middle red letter A)

Unfortunately I didn't get them centred over the holes and the slope was too sharp.

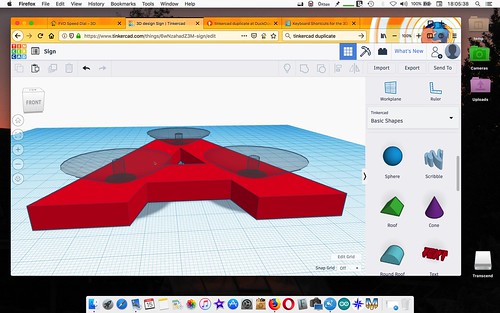

Back to TinkerCAD to try again.

The holes are made with thin cylinders.

The countersinking made with inverted cones and nicely aligned after much jiggling.

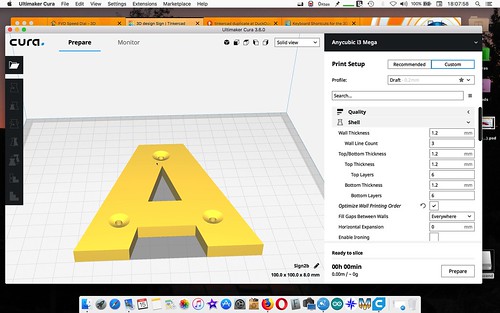

Saved and the file loaded in Cura

Reduced the infill to 8% and speeded up the extruder moves.

That brought the time down to 2h 45m

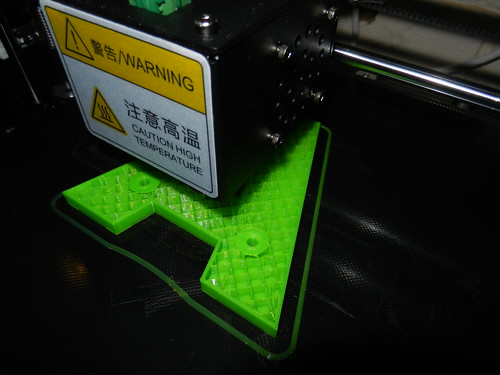

That print (in green above) looked much better.

I bet those holes took some doing. Thought my ears were burning.

ReplyDeleteJob is looking good. I've sent an email.

Are you thinking of a fancy font? You could do one in Inkscape and then import the SVG file.

Adrian: The holes will be easier next time round now the learning curve has levelled off.

DeleteTinkerCAD is very simple in that you can only use what is built in. Don't think any other fonts are importable.

It will be possible to construct a copy of your example. A couple of cylinders and part of a cone which can be locked together once made. Must check that a composite shape can be duplicated.