Last week I was experimenting with printing 3D nuts and bolts / screws.

FreeCAD includes data for many standard sizes.

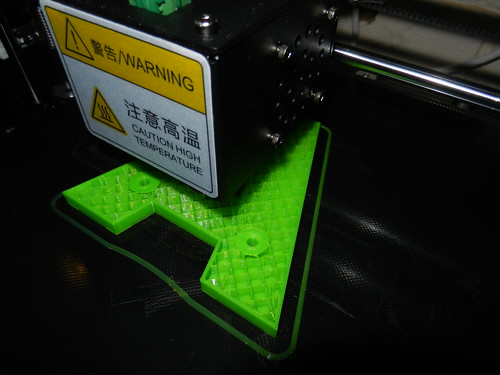

This is a 12mm screw + nut:

What I found was when printing a 12mm screw and then the corresponding 12mm nut, the nut was slightly too small and wouldn't fit. In the end I had to increase the size of the nut in the X and Y directions by about 10% in Cura to produce one which fits.

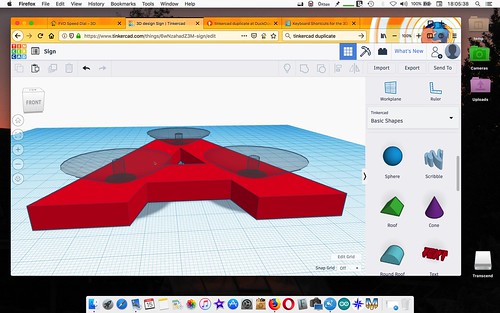

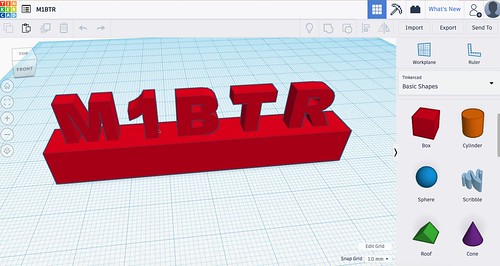

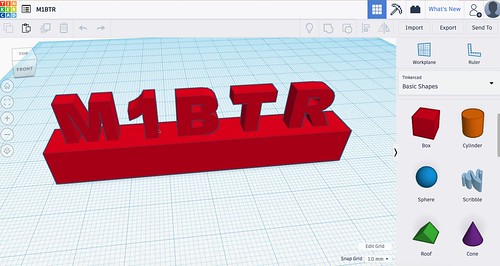

This week I have had a look at TinkerCAD. This is an on line 3D modelling site run by Autodesk.

Free to join up and experiment with. One can start with basic 3D solid shapes and 'tinker' with them to produce whatever your imagination can come up with. An ideal site for beginners to CAD (computer aided design), such as myself.

Once I had gone through all the basic tutorials what to build as a first project?

A small free standing sign with my amateur radio callsign came to mind.

The base is made from a basic cube, stretched and resized.

Fortunately a block letter alphabet is included in the choice of 3D shapes.

These were added singly, rotated and moved to fit on top of the base block.

There are very easy, once learned, facilities for aligning the various parts.

Once designing was finished the project was saved to the laptop as a .stl file.

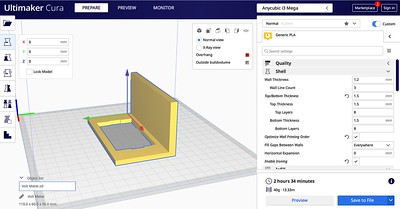

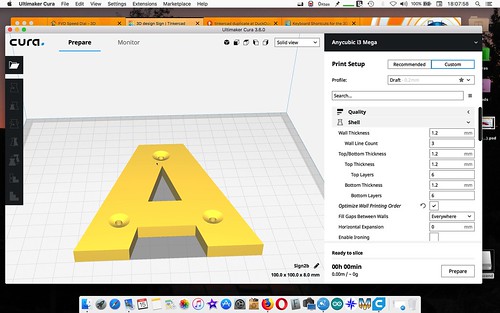

Then loaded in Cura to produce the instructions for the 3D printer.

Temporary thin supports had to be included in the instructions for sections of the design which would be created overhanging the base level.

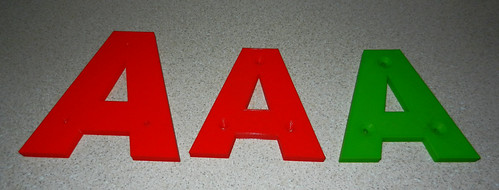

Resulting 3D print:

Once the temporary supports had been removed:

The base may look as though it is a solid lump but it is mainly hollow with a 20% infill of criss cross supports. Total print time 1hr 9min..