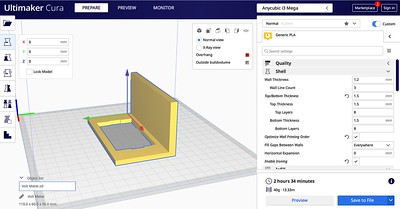

The instruction were copied to Ultimaker Cura to produce a file for the 3D printer.

Unit rotated to print face down. No supports needed that way round.

2hr 34 minutes later it was ready to fit the meter:

Had to do a bit of minor filing as the hole was about 0.5mm too small but soon it was mounted, wired up and connected:

All done.

A bit more practise and you will be able to bin the files. It is a good job done. Looks perfect.

ReplyDeleteI suspect your printer is the better option. That resin spray thing Mark had was a pain. I had to make B&W slices at silly intervals to get it to work and I guess it doesn't as he has bee quiet for ages. It usd to sag on the printer plate unless you ran it slowly. The pattern makers down the road have a big one for doing patterns and cores for casting. Not seen it but I wonder how long they last. Those flask compressors give stuff some serious grief.